SEWER AND MANHOLE RENOVATION WITH OUR DURA.PC SOLUTION

Especially with old, brick-lined sewers, the section of pipes to be renovated can include cross-sectional changes, curves and bends with different radiuses. This is where the superior flexibility of the DURA system proves its worth, with its individual capabilities for perfectly adapting all forms to varying cross-sectional geometries. What‘s more, the optimal bend flexibility of the elements can be produced using an angle without great effort.

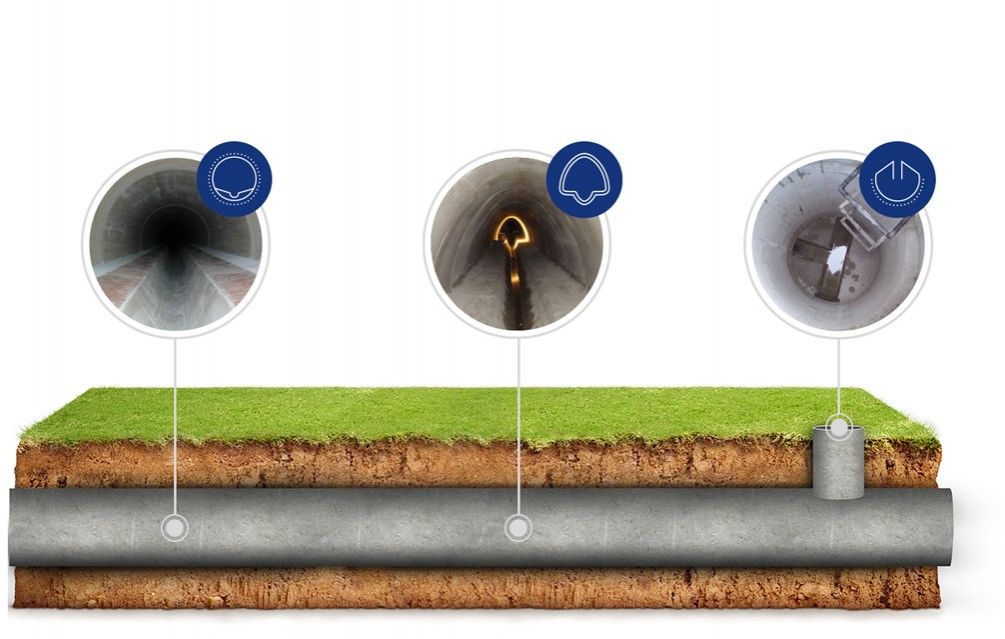

COMPLETE AND PARTIAL RENOVATION FOR SEWERS AND MANHOLES

SEWER RENOVATION. PARTIAL OR COMPLETE.

Here, for example, the invert of the drain to be renovated is lined with thin-walled, corrosion-proof shells. This kind of renovation is particularly suitable for drains with right-angled or even acute-angled corners. The renovation sections are first put together inside the drain and are bonded together on site. In this way, the elements can be taken into the sewer even through tight manholes.

Bonding polyceramics is considerably more straightforward than bonding other mineral materials. If necessary, the entire arch of the drain can also be lined with a shell composed of individual elements. In addition to this solution, many other components are available to meet your individual needs.

NEW SEWER CONSTRUCTION. OPTIMIZED RETROACTIVELY.

With newly constructed drains made with round pipes, a long-lasting, corrosion-resistant dry-weather channel can be created with the retroactive fitting of a polymerceramic invert shell. For the corrosion-proof lining of the channel in egg-shaped sewers and an in-situ concrete construction process, a one-meter-long invert shell is available. The resulting low number of joints means especially cost-effective production. Special components with added manhole elements, terminations and bend elements complete the system.

MANHOLE RENOVATION. SYSTEMATICALLY REFURBISHED.

As a rule, manhole renovation takes place in two steps. First, the base of the manhole is restored with specially cut-to-fit half shells and prefabricated polymerceramic berm plates. The rising manhole section is lined with corrosion-proof and abrasion-resistant elements of the same material, bonded into rings inside the shaft. The thin walls allowed by the material are particularly beneficial, allowing a maximum of free space to be retained. We are happy to advise you when choosing the right elements for your renovation plans.

WHAT IS POLYMERCERAMIC?

Polymerceramic is a high-quality, extremely wear-resistant build-ing material. Its outstanding material characteristics predes-tine it for use in sewer and manhole applications that place the highest demands on mechanical toughness, long-term abrasion resistance and chemical durability. The material is impermeable to water and exhibits extremely low moisture absorption. This makes all DURA components resistant to frost and weathering.

| Compressive strength | > 80 N/mm² |

| Flexural strength | > 20 N/mm² |

| Elastic modulus | 20.000 N/mm² |

| Abrasion resistance | 0.14 mm wear after 100,000 cycles (Darmstadt method) |

| Chem. durability | pH2 to pH12 |

| Temp. resistance | Sustained temperature resistance up to 80°C |

| Moisture absorption | < 0.13 percent by weight |

| Fire protection class | B1 (flame retardant) |

DURA pipe walls and fittings are made from impermeable polymerceramic, the ideal material for reliably watertight sewer components. With a service life of up to 100 years, DURA elements deliver long-term, trouble-free and envi-ronmentally secure functionality in renovated and retrofitted systems. They are the perfect fit for Steinzeug-Keramo‘s sustainability-based product philosophy.

- When being reliably watertight is top priority on your projects

- When low weight is crucial in deciding your choice of material

- When extremely long service life is a mission-critical factor

- When perfect dimensional stability under heavy loads is a must

- When you need sustained abrasion resistance under constant use

- When you have to ensure long-term, high-level chemical durability

- When frost and heat resistance are part of your project’s specifi-cations

- When you expect uniform wall structure and the highest level of precision in your components

Our consultants are happy to inform you about the strengths and opportunities offered by the DURA system.

Contact now