Pipe jacking

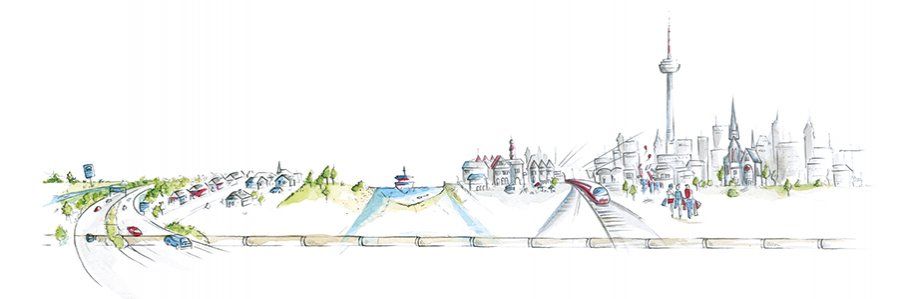

In comparison to the open construction method, pipe jacking is a trenchless construction method. Trenchless pipe-laying is carried out as far as possible underground, without the need to excavate soil above. It is largely underground, so that the overlying soil does not have to be removed.

The pipe jacking process offers a decisive advantage: while jacking pipes for the wastewater are installed beneath the earth's surface, life goes on almost undisturbed. Apart from the start and target pit — and depending on the length of the attitude of a few intermediate pits — there are no significant restrictions on the surface of the earth along the route. Thus, e.g. avoiding congested traffic routes, businesses with declining sales and cities of major construction sites thanks to pipe jacking. Noise and dirt are avoided as far as possible, CO2 emissions and particulate matter are minimized, roads are not torn up, and flora and fauna are protected. In short: Economic losses and environmental impact are minimized in trenchless pipe laying.

Trenchless construction offers an array of compelling advantages from the economic, environmental and societal points of view – and has done so for more than 30 years already.

Jacking pipes are subject to extraordinary stresses, and have to satisfy the highest demands, fulfill a multitude of special requirements, and be tuned to the dimensions and specificities of the jacking machines. The solution: pipe jacking with vitrified clay pipes. Vitrified clay jacking pipes demonstrate outstanding properties and, with their top-class technical specifications, are extremely well suited to the pipe jacking process:

- Perfectly parallel facings for uniform pressure transfer and tension distribution

- Ultra-precise cutting, milling and grinding of pipe spigots

- Stainless steel couplings

- Profiled gaskets (rubber elastomer) on the outer edges of the couplings to prevent soil entering the seal area

- Joint system internally and externally sealed to at least 2.4 bar (watertightness)

- Pressure transmission from pipe to pipe using chipboard

- Factory fitting of pipes, couplings and pressure transmission rings

- On-site assembly of bentonite adapters and injection nozzles

- Stainless steel threaded sleeves and sealing plugs

Various tunneling technologies are available for trenchless pipe laying, both for the construction of new pipe drives and for the renewal of jacking pipes:

NEW CONSTRUCTION

- Pilot pipe jacking

- with soil displacement

- with soil removal

- Microtunnelling

- with auger spoil removal

- with slurry shield

- Manned pipe jacking

RENEWAL METHODS

- Pipe-Eating

- Burstlining (related method)

The most important technologies for the construction of sewers are controlled pilot pipe jacking and microtunneling. Prerequisite for the use of the procedures is a detailed ground investigation. Further information on the jacking pipe technologies can be found in our brochure.